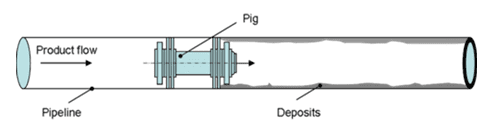

Pigging is a process used to clean pipelines of all kinds and for owners of medium and high head hydropower schemes, it can help to ensure that plants are generating as much power as they should. When a pipeline is pigged, it is cleaned by sending a bung, known as “pig”, down the pipe. The diameter of the pig closely matches the internal diameter of the pipe so as it moves down, it removes silt and any deposits on the walls. For hydropower plants, a pipe can be pigged with only minimal downtime. The pig is inserted close to the intake, using a pig launcher, and is driven down the penstock by the pressure of the flow. At the other end, the pig exits into a chamber or a removed section of pipe in the manifold. Any debris or build-up that the pig scrapes off will come flying out as well!

Why should I get my penstock pipe pigged?

For any hydropower scheme, there are a number of reasons why it is good to get your penstock pigged. Firstly, it will improve the performance of the pipeline. Any build-up of sediment reduces the flow passing through the pipe which also reduces the available head and therefore, the power output of the plant. Secondly, built-up debris that is left for a long time can lead to damage and degradation of the walls of the penstock.

What else do I need to be aware of?

Some hydropower schemes are designed with pipe pigging in mind. Often a special chamber will allow the pig and anything it washes out to be easily removed. At other sites, there may not be special provision for pigging making it a slightly more complicated process. Any pipeline can be pigged but some require more effort than others!

It is good to ensure that you know the diameter of the penstock all the way down the pipeline and be aware of the dimensions of any bends. This will allow the pig to be sized accordingly. You want the pig to be a good fit so that it clears away all of the deposits in the pipe but you do not want the pig to get stuck!

Watercourses with a high volume of peat usually result in large build ups on the inside of pipes. To maintain good power output, these penstocks may require more frequent pipe pigging, in some cases up to twice a year.

When pigging, a large amount of material is released from the penstock. Managing its return to the water course correctly is important. It is advisable to do pipeline pigging during spate flows, where the sediment content of rivers is already high and the pigging sediment can be diluted [1].

If you are the owner of a medium or high head scheme, contact Hydro Maintain today to discuss your pigging needs! Call us on 0330 1331 555 or email enquiries@hydromaintain.com.

References

[1] https://www.controleng.com/articles/dirty-pipelines-decrease-flow-production-pig-your-line [2] https://gov.wales/sites/default/files/publications/2018-11/permitted-development-rights-and-small-scale-low-risk-hydropower.pdf