Hydro Maintain undertake work on all kinds of turbines.

Archimedean Screw

The Archimedes Screw, as its name implies, has been around a long while and is still used for lifting or moving water in sewage plants or moving grain in grain stores. It is very simple with only one moving part and two bearings.

This lifting device can be used in reverse, where water travels down the screw, causing it to turn.

The screw turns much more slowly (normally between 20-30 rpm) than modern water turbines, which in itself has advantages in that it causes less damage to fish. In reality the water is not turning at all, it is the screw that turns and the water (and any fish) get a free ride down. The screw being “open” to the air means that the device operates at atmospheric pressure and so does not adversely affect the swim bladders of fish. Waterwheels are the only other devices that share this advantage.

Considerations:

- Fish friendly.

- Low pressure, so swim bladders of fish not affected.

- No draft tube so reduced civil costs.

- Can be as simple as a foundation of two concrete piers. High efficiency over wide range of flow – 100l/s-15m³/s

- No fine screening, so no trash cleaner and debris passes through high visual impact, mechanism visible.

- Normal rotation speeds 25-30rpm Only suitable for low head schemes.

Kaplan Turbine

At first glance a Kaplan turbine consists of a propeller, similar to a ship’s propeller. In low head situations the common six bladed design is reduced to three and the water flow is regulated by the movement of wicket gates. The blade pitch is simultaneously varied with the wicket gates to maintain high efficiency under partial flow conditions. The wicket gates are carefully profiled to induce tangential velocity (whirl) into the water flow. This complex engineering and the necessary control systems make Kaplan turbines expensive for both small scale and micro hydro installations.

Considerations:

- At designed flow rate most efficient

- All the mechanism can be architecturally hidden Relatively small mesh fish screens

- Automatic trash screen clearance needed in most Efficiency at low flow rate is poor.

- Complex control systems

- Penstock and tailrace design crucial to

- Civil works are extensive and need to be of high standard to warrant costs of turbine

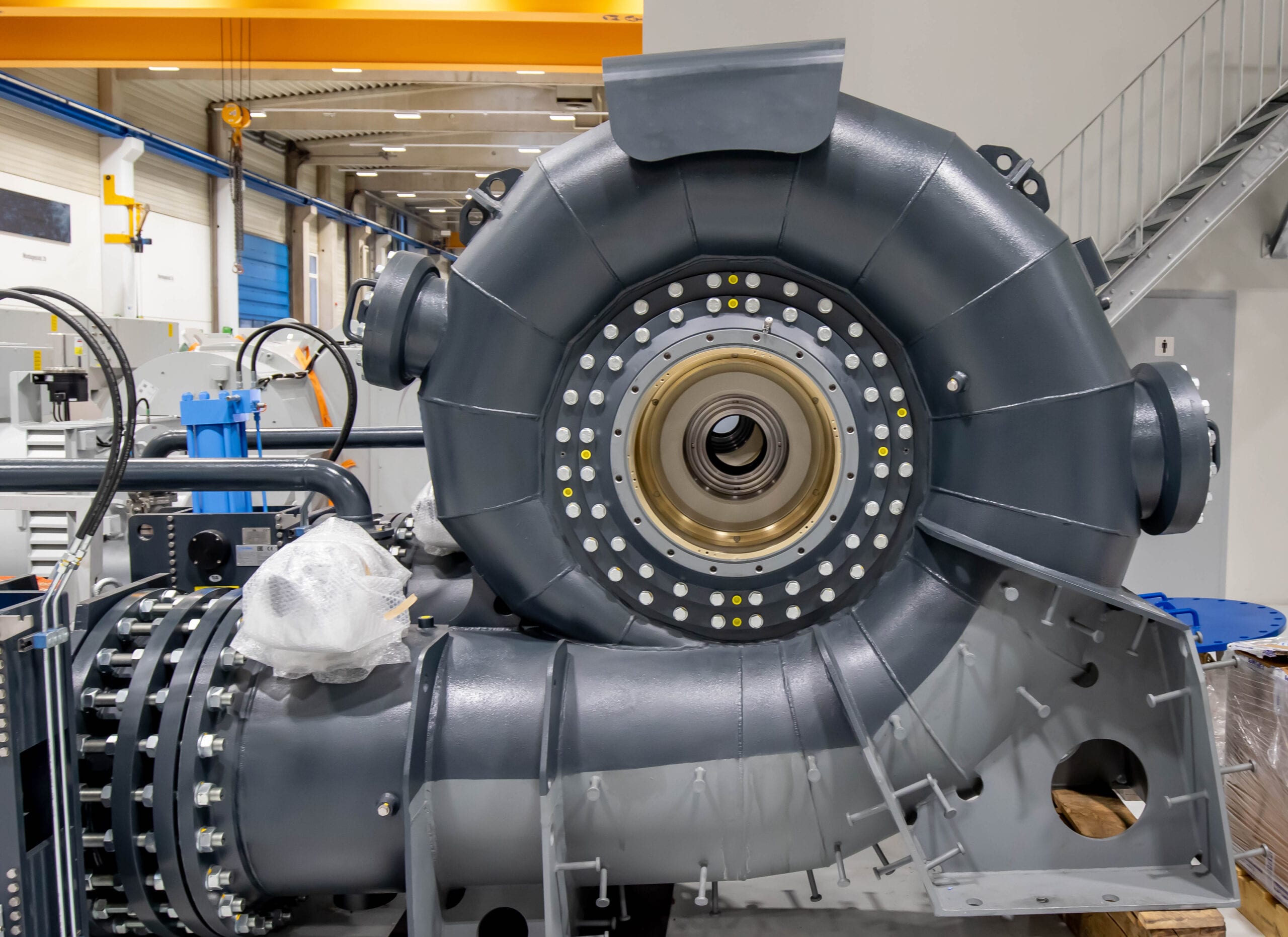

Francis

A type of hydropower reaction turbine that contains a runner that has water passages through it formed by curved vanes or blades. The runner blades, typically 9 to 19 in number, cannot be adjusted. As the water passes through the runner and over the curved surfaces, it causes rotation of the runner. The rotational motion is transmitted by a shaft to a generator.

The Francis turbine has a wide range of applications and can be used for fall heights of 2–800 meters. The largest Francis turbines have an output of 750 MW. Compare with Kaplan turbine and Pelton turbine.

Crossflow

A relatively simple impulse turbine Crossflows are often deployed were the cost of manufacturing a Francis would be prohibitive. Crossflow turbines are unique in that water flows through the runner transversely, hence the name Crossflow. Water enters a Crossflow in a flat section striking the flat blades of the runner before passing through and meeting the blades a second time as it leaves.

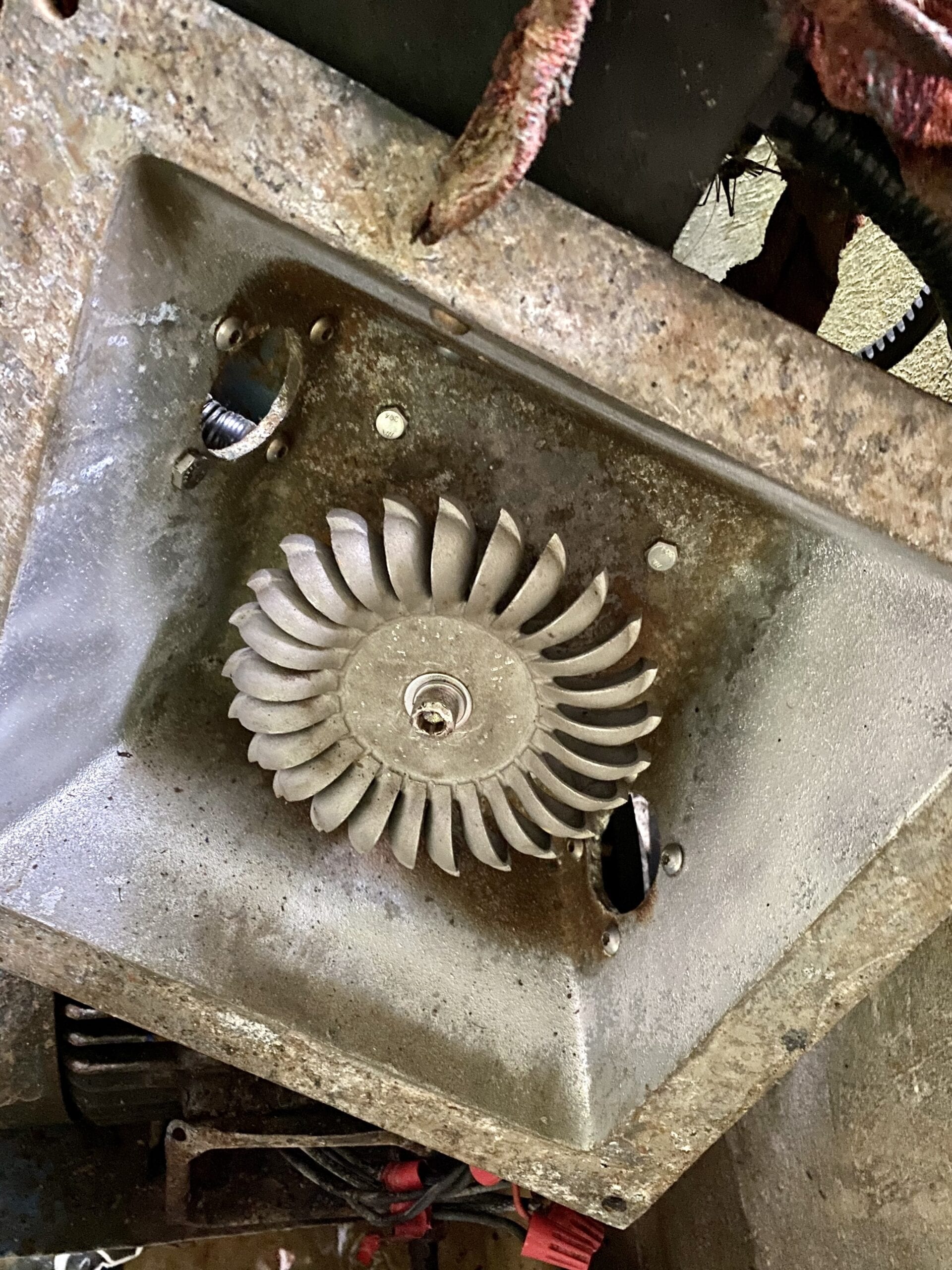

Pelton Turbine

Once the available head starts to increase then the Pelton wheel becomes the technology to use, being both efficient and having a long life. The runner is basically a wheel with cups mounted around its rim. The devices can work with single or multiple jets.

A common variant on the Pelton wheel is the Turgo wheel where the jets of water strike the wheel at an angle instead of directly.

Considerations:

- normally 20m minimum head

- cost of penstock

- installation can involve multiple landowners

- civil works can be very basic

Turgo

A Turgo turbine is an impulse turbine like Pelton turbine which has been sliced in half and it is able to handle high flow rates but at lower efficiencies. In this turbine, the water jet hit the plane of the wheel in an angle of about 20° and exists on the other without interfering with the incoming water jet. This process allows the turbine to handle high flow rates. Its design has a larger diameter and speed which generates about the same amount of power that a Pelton turbine would. Another difference between Turgo and Pelton turbines is that a Turgo’s vanes are smaller and sometimes difficult to manufacture.

In some cases, the small spinning runners can be connected straight to a generator without a transmission system because a Turgo turbine already produces high speeds.

This turbine operates in the same range as Pelton and Francis turbines. Turgo installations are very popular for microhydro installations.

TYPES OF TURBINE

In a reaction turbine the blades (runners) are fully immersed in water and are enclosed in a pressure casing. The blades are angled so that pressure differences across them create lift forces, like those on aircraft wings, and the lift forces cause the runner to rotate. Reaction turbines are most common on low head applications.

In an impulse turbine the runner operates in air, and is turned by one or multiple jets of water impinging on the blades. A nozzle converts the pressurized low velocity water into a high-speed jet much like you might use with a garden hose nozzle.